Products Description

FEATURES AT A GLANCE

Robot application

In industrial production, industrial robots can replace people to do certain monotonous, frequent and repetitive long-term

operations, or operations in dangerous and harsh environments, such as stamping, pressure casting, heat treatment, welding,

painting, plastic product forming, In processes such as mechanical processing and simple assembly, as well as in the atomic energy

industry and other sectors, complete the handling or process operations of materials harmful to the human body.

Key technologies include:

(1) Open and modular control system architecture: adopts distributed CPU computer structure, divided into robot controller (RC), motion controller (MC), photoelectric isolation I/O control board, sensor processing board and programming display Teaching box and so on. The robot controller (RC) and the programming teaching box communicate through the serial port/CAN bus. The main

computer of the robot controller (RC) completes the robot's motion planning, interpolation and position servo, main control logic, digital I/O, sensor processing and other functions, while the programming teaching box completes the display of information and the input of keys.

(2) Modular and hierarchical controller software system: The software system is built on the open source-based real-time

multitasking operating system Linux, and adopts hierarchical and modular structure design to realize the openness of the software system. The entire controller software system is divided into three levels: hardware driver layer, core layer and application layer. The three levels face different functional requirements and correspond to different levels of development. Each level in the system is composed of several modules with opposite functions. These functional modules cooperate with each other to realize the functions provided by the level.

(3) Robot fault diagnosis and safety maintenance technology: Diagnosing robot faults through various information and performing corresponding maintenance are the key technologies to ensure the safety of robots.Keywords: robot arm 6 axis 6 axis robot arm 6 axis industrial robot arm 3 kg robot arm 6 axis oem 6 axis robot arm 10kg arm robot

6 axis 6 axis milling robot arm mini 6 axis robotic arm 6 axis robot arm oem 6 axis robot arm milling machine robots 6 axis

industrial robot arm 6-axis robot arm woodcarving robot arm 6 axis industry industrial robotic arm 6 axis robotic arm 6 axis 200cm for laser welding gun robot-arm-6-axis-collaborative-robot 6 axis industrial robot arm

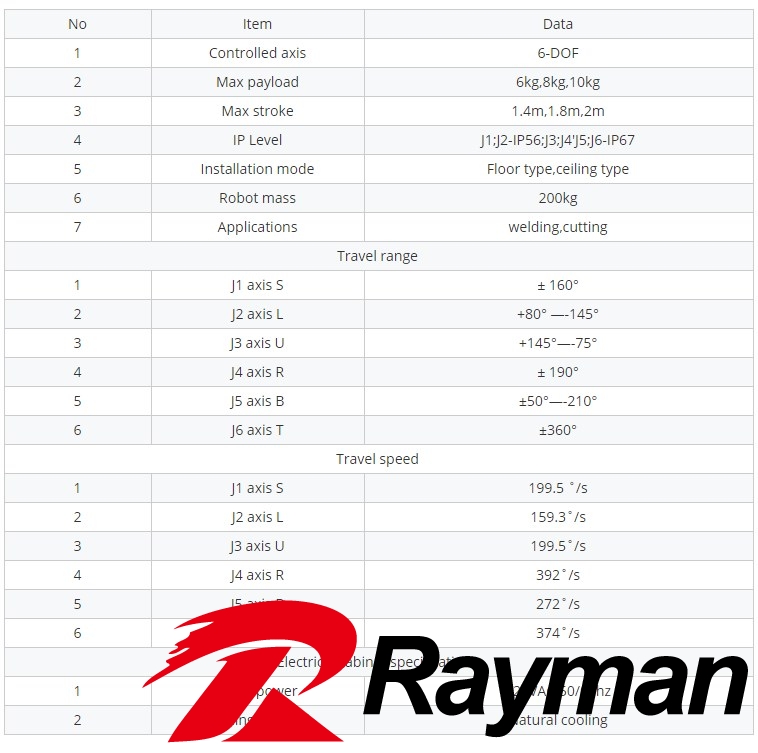

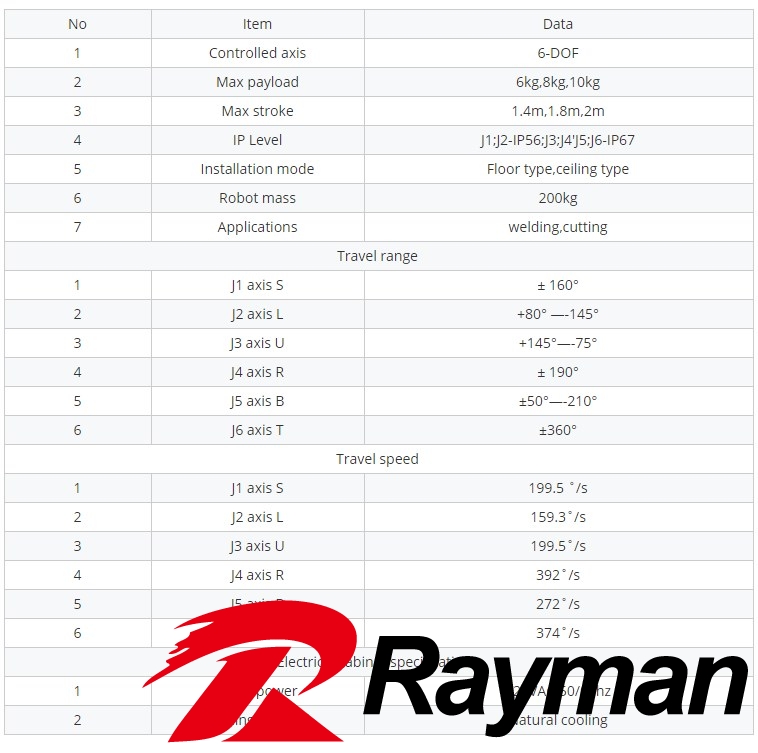

Product Parameters