Technical parameter

| No. | Technical specification of Portable cnc plasma cutting machine | |

| 1 | Model | RM-1530 |

| 2 | Power source | AC 220/380±10%VAC 50/60Hz |

| 3 | Cutting mode | O2/C3H8 or C2H2 Plasma cutting+flame cutting |

| 4 | Effective cutting range(mm) | 1500*3000 |

| 5 | Input Voltage | 220V, 50HZ |

| 6 | Cutting speed(mm/min) | 0-8000mm/min |

| 7 | Cutting thickness(Flame)(mm) | 6-160 (O2/C3H8 or C2H2) |

| 8 | Move precision | ±0.2mm/m |

| 9 | Torch | Flame, electric height adjustment(±60mm) |

| 10 | Processing thickness(mm) | 0.5-15mm |

| 11 | Cutting system | Start control system |

| 12 | Host weight(kg) | 19 |

| 13 | Total weight(kg) | 120 |

| 14 | Gas pressure(Mpa) | Max.0.1 |

| 15 | Oxygen pressure(Mpa) | Max.0.7 |

| 16 | Type of gas | C3H8 C2H2 |

| 17 | Emergency stop | Yes |

| 18 | Working temperature | -5~45℃ |

| 19 | Power | 8.5kw |

| 20 | Plasma power | 40A to 200A |

Machine part

1.Control system is F2100B,which is very popular in China,with large graphics library,and easy to learn to operate.

Support 19 languages(Chinese, English, Russian, Spanish, Portuguese,Nederlands, French, Japanese, Korean and so on).Also could be other language as buyer demand.

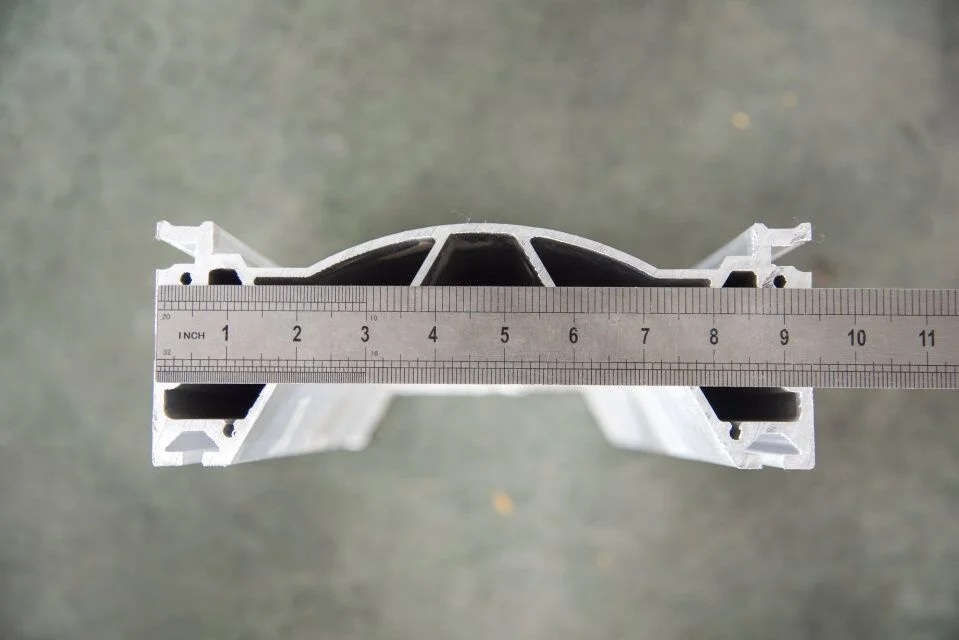

2.Aluminum structure guide and rail, Excelent balanced patent design, Geometric design,weighing more and wont bent after long time working, make sure high move precision and cutting precisioin.

3. Lifting station to take cutting torch up and down; Use Leadshine stepper motor, ball screw to transform; more steady and smooth

4.Each 8 pcs big bearing rollers for X axis guide and Y axis rail; which installed with duo ball guiding rails;

Rollers tached rails tightly in different points, to make sure moving steady and moving precision.

5.Torch Height Controller: Shanghai Fangling F1620

Product Introduce

Portable numerical control flame/plasma cutting machines can be programmed to cut any plane shape parts composed of beeline and arc ,which are same as large gantry cutting machines .

It is equipped with a 5.7 inch LED with dynamic and static graphical display .It is directly perceived and very easy to learn .It can be programmed to cutting parts directly , and also can be operated in computer translating instructions into a program file by CAD program , and then deducing it via U hardware .

Cutting Smaple