Portable plasma cutter can cut mild steel, high carbon steel, stainless steel, aluminum, copper and other non-ferrous metal, etc.

It is widely applied in industries such as automobile, shipbuilding, machine tools, pressure vessels, engineering machinery, mining machinery,electric power, building bridges, steel Industries.

|

Technical Specification |

|

|

Model |

RM-1530 |

|

Effective cutting range(mm) |

1500×3000mm |

|

Cutting speed (mm/min) |

50-4000(max. 4000) |

|

Input power source |

380v±10% VAC,50/60HZ,Three phase |

|

Input Machine body |

220V±10%V AC, 50/60HZ, Single phase |

|

Flame Cutting thickness (mm) |

6-200 (Oxygen + acetylene or propane) |

|

Plasma cutting thickness(mm) |

0.3-35mm( with different plasma power source) |

|

Torch height controller |

F1621 |

|

Flame cutting gas |

Oxygen+ propane or acetylene |

|

Plasma cutting gas |

N2, O2 or compressed air |

|

Cutting torch |

One piece flame cutting torch and one plasma cutting torch with plasma power source |

|

CNC controller system |

F2100B |

|

Motor |

Leadshine Stepper motor and drive |

|

Operation precision |

±0.2mm/m |

|

Guide length ×guide width ×guide thickness (mm) |

3500×273×60 |

|

Nesting software |

StarCam / Fastcam |

|

Gas pressure (Mpa) |

0.5 |

|

Cutting tool Conversion Kit |

Oxygen(flame) and plasma cutting machine spare parts can change easily. |

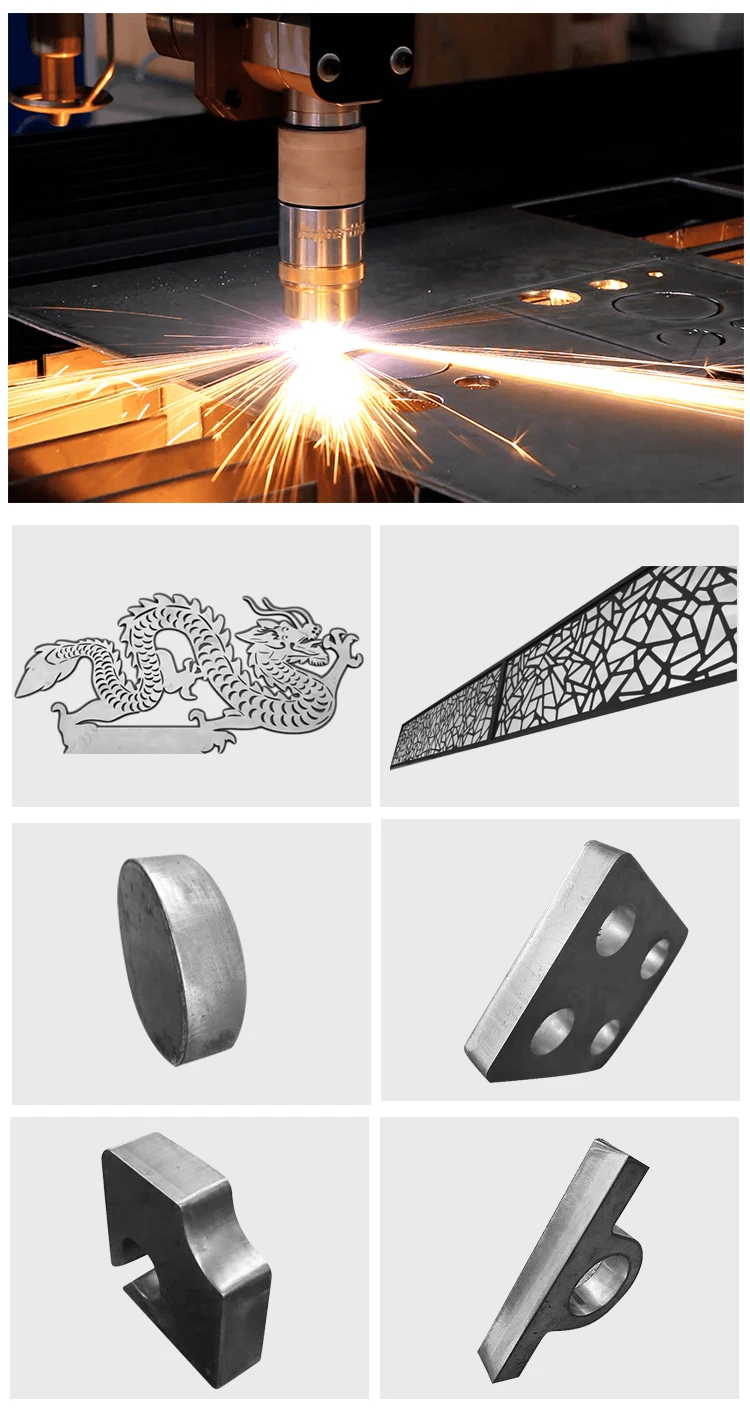

Machine and details pictures :

Cutting samples