LGK series inverter type air plasma cutting machine, Is a new design of metal processing equipment, Insulated gate high

power transistor IGBT and pulse width modulation (PWM) soft switching technology are used to design and manufacture.

The cutting machine can cut all metal materials, especially suitable for "flame cutting" can not achieve high alloy steel and

non-ferrous metals. The seriesof cutting machines have reasonable static and external characteristics, and also have

good dynamic characteristics, With high frequency arc starting function .Widely usedin all kinds of machinery

manufacturing industry. According to the CISPR11 requirements, the electromagnetic compatibility of the equipment is

classified as: class a..

Parameter

| Model | LGK-70IGBT | LGK-105IGBT | LGK-120IGBT | LGK-160IGBT | LGK-200IGBT | LGK-300IGBT | LGK-400IGBT |

| Rated input voltage |

3~380V/50HZ | ||||||

| Rated input capacity |

15.6KVA | 17.8KVA | 22.4KVA | 32.2KVA | 46.5KVA | 65.4KVA | |

| Rated Output current |

70A | 105A | 120A | 160A | 200A | 300A | |

| Rated output voltage |

100V | 120V | 128V | 144V | 160V | 200V | |

| Rated load sustainability |

100% | 100% | 100% | 100% | 100% | 100% | |

| No-load voltage |

300VDC | 300VDC | 300VDC | 315VDC | 315VDC | 380VDC | |

| Regulating rangeof current |

30~70A | 30~150A | 30~120A | 30~160A | 30~200A | 30~300A | |

| High quality cuttingthickness |

0.3-12mm | 0.3-16mm | 0.3-20mm | 0.3-25mm | 1-35mm | 1-45mm | |

| Maximum cuttingthickness |

20mm | 25mm | 30mm | 35mm | 45mm | 55mm | |

| Use of plasma gas |

compressed air |

compressed air |

compressed air |

compressed air |

compressed air |

compressed air |

|

| Working gas pressure |

0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | 0.4~0.6MPa | |

| The cooling method of cutting torch |

air-cooled | air-cooled | air-cooled | air-cooled/ water-cooling |

air-cooled/ water-cooling |

air-cooled/ water-cooling |

|

| Arc ignition mode |

Non contact mode | ||||||

| Insulation grade |

F | ||||||

| Shell protection grade |

|||||||

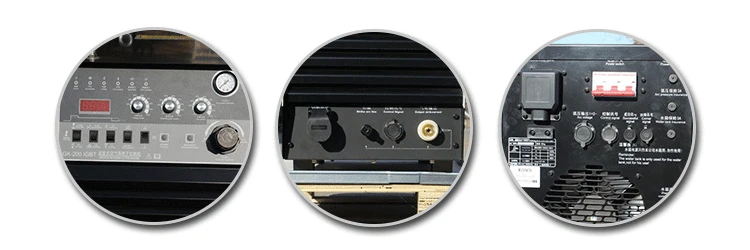

Product Details

Main Feature

The arc energy is highly concentrated, with good stability and strong cutting force

Cutting speed (3-5 times of gas cutting)

Cutting costs are low

Incision stenosis. Clean and tidy; close to vertical.

Small deformation of workpiece

The cutting current is adjustable continuously

Easy arc setting

The operation is very convenient

Light weight, small size, easy to move

High efficiency, high power factor, it is a kind of energy saving equipment.

Low noise and strong adaptability

Has two functions of self-locking and non self locking, adapt to the length of slot without

requirement, can reduce the labor intensity of workers.

Easy to form cutting equipment