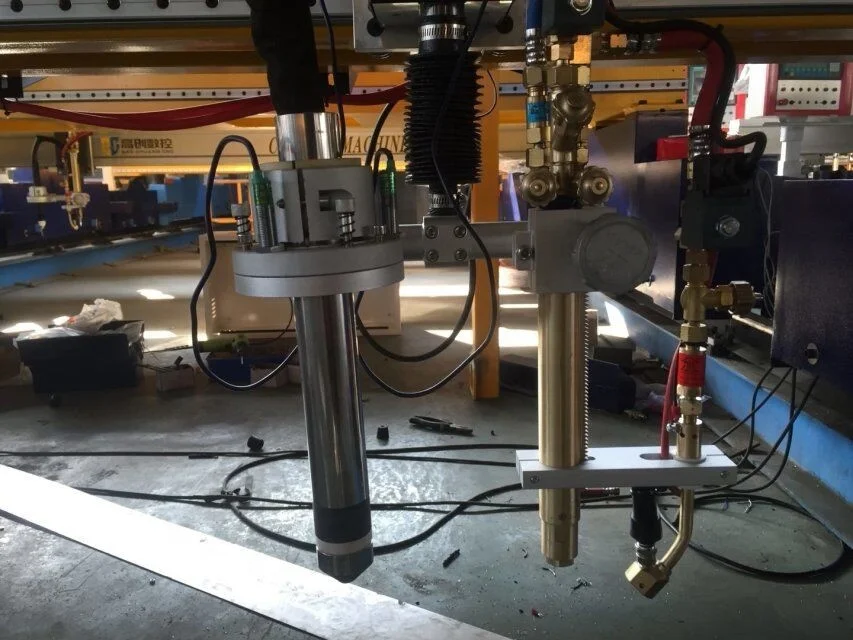

CNC series of gantry type drilling and cutting machine is a newly developed product by JIAXIN. It combines the advantage of drilling and cutting together. Due to the CNC plasma and flame cutting machine does not perform well in cutting holes in small dimension, especially in situation the diameter of the hole is smaller than plate thickness. In such case, we introduce a CNC drilling unit to finish the holes instead of the plasma or flame cutting. Plasma marking and zinc powder marking are available on the machine as well to mark the cutting path, drilling position and welding path before practical application. CNC drilling and cutting machine is very practical, economic and efficient in metal sheet processing, especially for the required parts with small holes.

1. Easy and quick operation

Pioneering field adjustable cutting torch height control, over the cutting torch raised control body design has all the necessary movement and control keys, to mobile operators in the cutting torch counterpoint is very convenient. Humanized design, more efficient operation.

2. Professional design, beautiful and atmosphere, more durable

All keys, all adopt the top design of crystal buttons, relative to other enterprises film button, button always ensure that clear bright, never wear. At the same time, the host body all adopt the technique of the lacquer that bake, colour is beautiful and durable.

3. Simple and straightforward way of graphics programming

Complex graphics CAD design is used in the office, the U disk into the cutting machine, simple graphics can also be on the cutting machine using a very simple and straightforward way programming input directly, such as "straight line, the fourth quadrant, X40, Y30". This way of programming, ordinary operators are very easy to learn.

4. A fool type operating mode

Screen below a reminder of various operating methods, the operator can do not need training, does not need to look at the instructions.

♦ Drilling and cutting the work piece automatically after programming, dispense further positioning the holes on work piece, high precision on drilling finish.

♦ Gapless gearing transmit, stable and smooth running in high speed, smart, fine surface finish quality.

♦ Integrated auto-ignition with automatic height controller, keep the height between the JIAXIN and work piece, achieve the best cutting quality.

♦ Able to process multi-torch mirror image cutting or synchronism cutting, improve cutting efficiency.

♦ Low use cost, dispense with special maintenance, friendly operator inteface, easy to learn.

♦ Utility CNC system, reliable and safe, automatic programming, optimization nestling and piercing patch, save the steel effectively.

|

Technical Specification |

|

|

Model |

CNC |

|

Machine dimension (mm) |

Maximum 12 meter in width and not limited in length |

|

Effective processing area (mm) |

1 meter less in width and 2 meter less in length than machine size |

|

Suggested cutting thickness (mm) |

Stainless steel:1-50mm and Carbon steel:6-160mm |

|

Drilling capacity (mm) |

Maximum 140mm in depth and 35mm in diameter |

|

Drilling power |

8Kw (25hp) 1Kw=1.36PS=1.34HP |

|

Drilling feed |

10m/min (400ipm) |

|

Drilling torque |

200 N.M. (150 ft-lb) |

|

Borehole pressure |

11000 N (2500 lbf) |

|

Cutting Speed (mm/min) |

50-9000 |

|

Running speed (mm/min) |

12000 |

|

Basic components |

|

|

Cutting Mode |

Oxy-fuel/ Plasma/ High definition plasma/ Laser |

|

Drive mode |

Servo motor, Dual-side |

|

Guide track |

Straight ball-guide |

|

Cutting Torch Number |

Customer specified |

|

Driving Motor |

Panasonic from Japan |

|

NC Controller |

Micro EDGE pro, Shanghai KP, SJTU-SK |

|

Plasma Power |

Victory (Thermadyne), Kjellberg, Hypertherm, JIAXIN LGK |

|

Programming software |

FASTCAM |

|

Gearbox |

SEW or Neugart from Germany |

|

Other Data |

|

|

Working temperature |

- 10°C -45°C |

|

Humidity |

<90%, no condensation |

|

Surroundings |

Ventilation, vibrationless |

|

Power voltage |

3×380V±10% 50Hz/ according to user's local condition |

|

Operation language |

Multilingual and English available |

|

Options |

|

|

Powder marking |

available |

|

Under water cutting |

available |

|

Beveling torch |

available |

|

Strip cutting torch |

available |

|

Heating and cooling system |

available |

|

Integration dust extraction |

available |

|

Thin plate processing device |

available |